Rethinking supply chains for an uncertain world

Global risksArticleApril 28, 2022

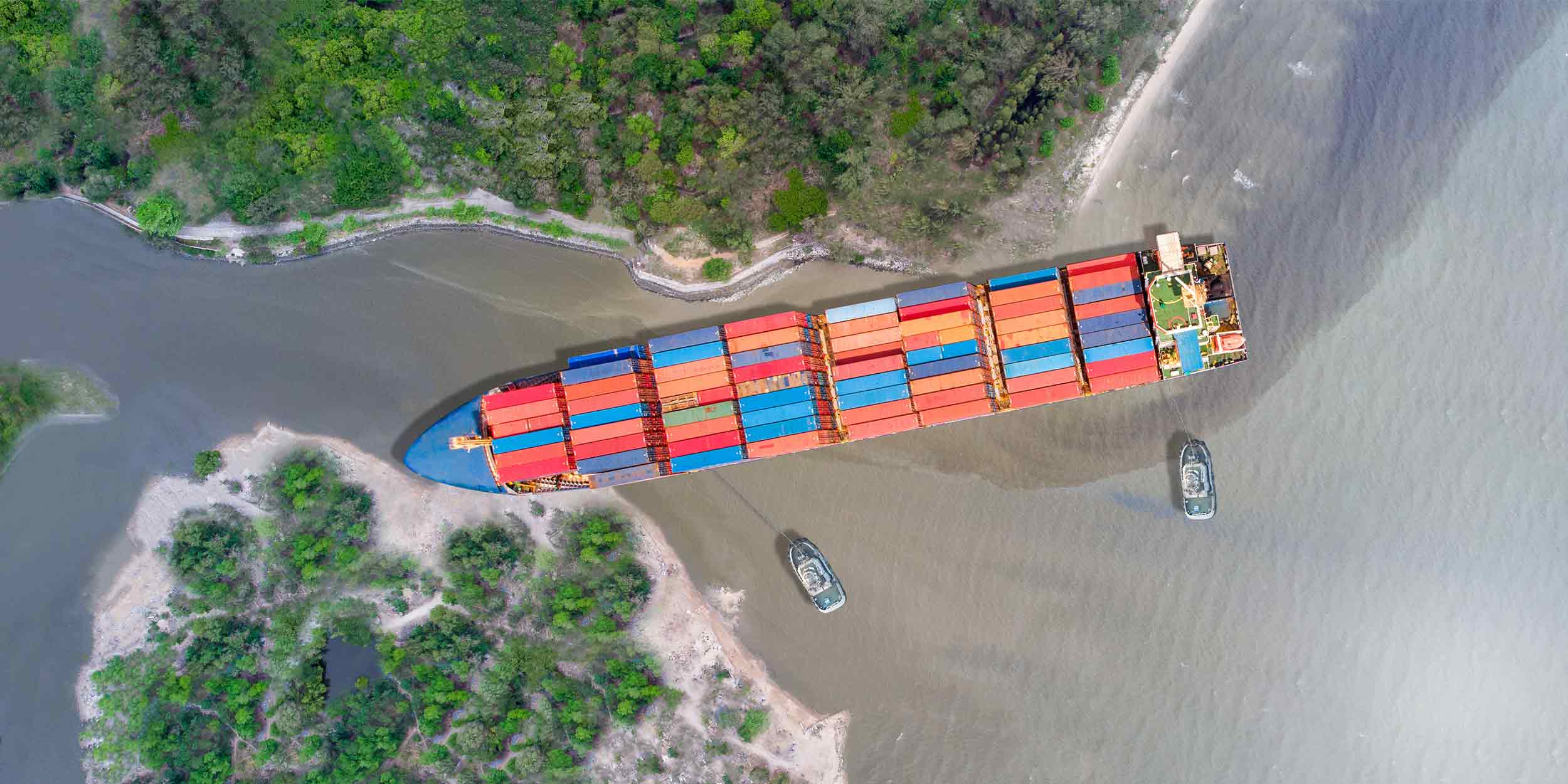

The profound disruption to the flow of goods around the world teaches companies to understand their vulnerabilities first to build greater resilience to future shocks

The last two years have seen one of the greatest upheavals to global supply chains in living memory.

The COVID-19 pandemic, which triggered national lockdowns from China to Europe and the U.S., and whose repeated outbreaks followed by severe lockdowns continue to pose profound challenges, upended supply and then paralyzed demand. More recently, Russia’s invasion of Ukraine has sparked energy price spikes, inflation and mounting concerns over food security.

As Larry Fink, Chairman and CEO of investment group BlackRock, which oversees about USD 10 trillion in assets, wrote in his annual letter to shareholders last month, “the Russian invasion of Ukraine has put an end to the globalization we have experienced over the last three decades.”

But what does all of this mean for companies as they look to repair their battered supply chains, respond to changes in demand and build resilience? And how can organizations, which are already challenged by the transition to net-zero and heightened cybersecurity threats, find opportunity in the supply chain crisis?

Those questions have taken on greater urgency given that many companies are still operating in a quasi-holding pattern after responding to the pandemic by building up inventories, argues Björn Hartong, Risk Engineering Global Practice Leader for Supply Chain at Zurich Insurance Group (Zurich).

“A lot of companies are really looking at the supply chain and what they need to do for the long term, but most companies don’t really know for sure what to do,” he says. “We’re still very much in reaction mode and there’s very little planning going on.”

Jean-Pierre Krause, Zurich’s Chief Risk Engineering Officer, argues that the supply chain turmoil has served as an important reminder of just how integrated and connected the global economy has become. “Even local companies specializing in local produce have suddenly realized that they are far more dependent on global markets than they thought,” he says.

It has also exposed how little knowledge companies had of their supply chains prior to 2020: according to a McKinsey survey from last year, only 2 percent of the companies polled said they had visibility into their supply chains beyond tier-two suppliers.

Krause says that the first step for any company looking to turn supply chain disruption into an opportunity is to be deductive, looking more broadly for types of failure, damage and attrition across the entire value chain that could compromise core business goals. “Don’t start with specific risks in mind,” he says. “First, you have to understand where you are vulnerable and where it really hurts and, from there, you work back.”

Addressing these vulnerabilities will likely mean diversifying supply chains to reduce dependency on any given supplier. Meanwhile, localizing supply chains can help to address carbon emissions targets in the context of a company’s net-zero goals. But it can also reduce dependency on international logistics, which have been traumatized by the ongoing COVID-19 pandemic, and continue to suffer as a result of the Russia-Ukraine conflict: according to a report last year by the International Chamber of Shipping (ICS), more than 14 percent of the world’s seafarers are either from Russia or Ukraine – a figure that suggests the maritime shipping industry could see increasing labor shortages for some time to come.

Hartong says companies should try to make their supply chains more customer focused, matching marketing strategies with supply chains to concentrate on products that are either in stock or readily available. Yet he also acknowledges that the pandemic has upended consumer habits, making it much more challenging for companies to predict what customers are prepared to buy.

“You have to be customer focused, but customers have changed their way of living in the last two years,” he says. “Many companies are still trying to work out whether they will revert to their old habits, whether newly acquired habits will stick or whether a hybrid version of the two will endure.”

Vivien Bilquez, Zurich’s Principal Cyber Risk Engineer, insists that companies responding to ongoing disruptions should be investing in increased digitization of supply chains, which brings advantages such as data replication, recovery capabilities and data access traceability. At the same time, it is important to use artificial intelligence to anticipate, monitor and respond to future supply chain shocks.

But he also insists that companies should re-examine cybersecurity, which is an essential but often overlooked dimension of modern supply chains. “The multiple flows of data to and from a company are a central part of today’s supply chains, and any disruption, interception, redirection or eavesdropping of that data flow can compromise the entire company.”

Bilquez says that while many companies outsource their data processing services to cloud service providers, which can be less expensive than on premise and also more secure given that cloud services provide cybersecurity-embedded features and apply security patches systematically and quickly, they should document all outsourcing in a register and conduct greater risk assessments. And they should also ensure that contracts with cloud services include information security and data protection requirements which can be monitored through dashboards and specific alerting processes.

Business continuity and recovery capabilities, data portability, right to audit or right to exit are other important aspects that companies must have in their outsourcing contracts. “Companies should really pay close attention to their data contracts as a basic part of making sure their supply chain is resilient,” he says.

Ultimately, argues Hartong, overcoming today’s challenging supply chain environment requires planning on a scale – and with a depth – few companies have undertaken before. “It sounds like a contradiction, but companies need to get used to expecting the unexpected – and to be prepared for it when it happens.”